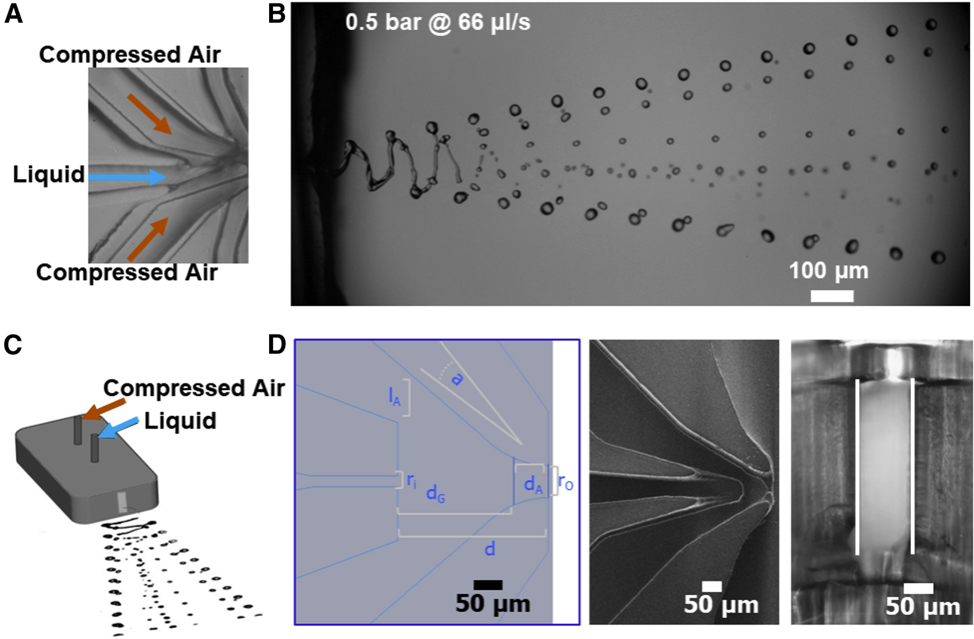

A multinational team of researchers, led in part by BSISB program director Hoi-Ying Holman, recently announced the discovery of a new type of aerosol-producing technology, dubbed the ‘whipping jet.’ Aerosol technology has the potential to impact many fields of science, from experimental studies of atmospheric aerosols to delivery of aerosolized medications.

The collaboration included Martin Trebbin of SUNY at Buffalo College of Arts and Sciences, Sankar Raju Narayanasamy of the Lawrence Livermore National Laboratory and an LBNL affiliate, and Ramakrishna Vasireddi of SOLEIL, the French synchrotron facility in Paris.

The technology delivers a highly reproducible 2D array of droplets of various sizes based on the whipping action of a fine-scale nozzle. This technology marks a third-generation advancement in the control of liquid jets, after cylindrical jets were developed in 1998 and flat liquid sheet jets, in 2018.

The team’s recent open-access publication in Cell Reports Physical Science earned further recognition as the journal’s cover art this past January (2023: Volume 4, Issue 1). The work was also highlighted in a press release by SUNY-Buffalo, in an article by Elements, the news and information source for the Berkeley Lab community, and in a story published by the American Association of Universities.

Observe the ‘whipping jet’ in action:

Funding Acknowledgements

This work was supported by the U.S. Department of Energy, Office of Science, Office of Biological and Environmental Research under Contract No. DEAC02-05CH11231.

Related Links

- U.S. Department of Energy BER Highlight: Unelectrified Aerosol-Producing Device for Biological Studies

- LBNL Biosciences: Whip It: Novel Liquid Jet Makes Droplets March to the Beat

- University at Buffalo News Releases: New ‘whipping jet’ sprayer controls how aerosols move

References

- Narayanasamy SR, Vasireddi R, Holman HYN, and Trebbin M. A sui generis whipping-instability-based self-sequencing multi-monodisperse 2D spray from an anisotropic microfluidic liquid jet device. Cell Reports Physical Science, 4(1): 101221. (2023; https://doi.org/10.1016/j.xcrp.2022.101221)

By Liz Boatman